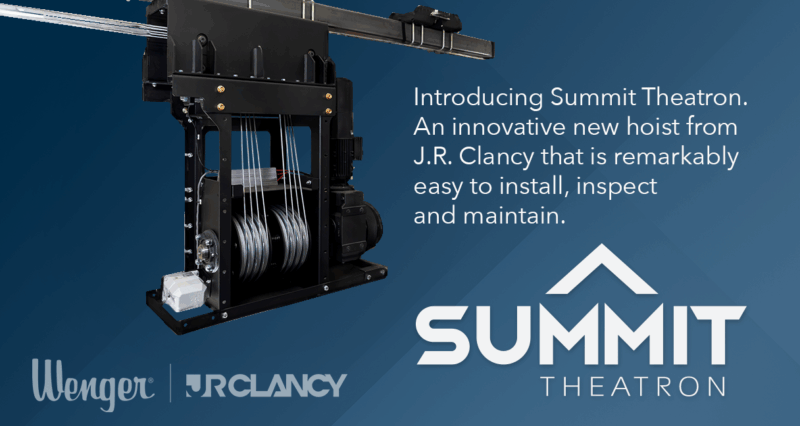

Wenger Corporation, a leading provider of innovative products and solutions for the performing arts and music education, is proud to introduce its new Summit Theatron™ hoist, a revolutionary rigging solution especially for high school theatres, university theatres and worship venues.

With smart innovations that improve both performance and safety, installation options that offer greater adaptability and an inspection-friendly design, the new Summit Theatron hoist simplifies rigging cost-effectively for dealers, specifiers and end users without compromising on quality.

“For 140 years, J.R. Clancy has led the industry in rigging innovation, driven to create solutions that elevate the performing arts safely,” says Dave Thomas, President and CEO of Wenger Corporation. “This new Summit hoist proudly continues our tradition of excellence in listening to our customers.”

Precise Performance

The Summit hoist charts a new path in rigging technology. It’s available in low- and high-speed models: 2,200-lb. (998 kg) capacity at 30 fpm (0.15 m/s) for stage electrics and acoustical shells; and 1,500-lb. (680 kg) capacity at 205 fpm (1.0 m/s) to match the pace and performance of manual rigging. Variable Frequency Drive ensures smooth starts and stops, helping protect sensitive and expensive sets, lighting and acoustical shells.

Flexible Installation

For easier, faster installation in a wide range of performance spaces, the Summit hoist features a patent-pending backbone – separate from the motor head – that enables variable mounting options. Typical 8-inch (203 mm) set spacing is possible by alternating hoists between both sides of the stage or by offsetting hoists on one side of the stage.

Hassle-Free Inspection

Routine inspections and maintenance are simplified by the Summit hoist’s open-frame design with multiple access panels. Technicians can easily inspect the gearbox and drum, reducing downtime and ensuring optimal, safe performance.

Key Features

- Travel Cable Size and Number of Lines

- Travel- 55’-0” (16.8 m)

- Cable Size- 3/16” (4.8 mm)

- Number of Lift Lines- up to 8

Safety Features

- Load sensing standard

- Redundant load braking system

- ANSI E1.6-1 compliant

- Redundant end of travel limit switches

Operational Features

- Repeatable positioning within 1/4” (6.3 mm) via absolute encoder

- VFDs on all models. This ensures soft starts and soft stops

Mounting Features

- Optional continuous beam eliminates the compressive forces on the building structure and is perfect for open bar joist construction

- Flexible mounting clamps to accommodate various beam spacing

- Hoist backbone allows variable mounting locations for both the hoist and loft blocks

- Set spacings as close as 8” (203 mm) center to center with hoists staggered under hung unit

Additional Features

- 018-S0322 available at 208V and 480V

- 018-S2015 available at 480V only

Further information about Wenger: www.wengercorp.com