LEWISBURG, PA – Bucknell University's Weis Center for the Performing Arts recently upgraded their automated rigging control system with the Altus system from J.R. Clancy. The Weis Center is the primary concert hall and performance space for theatre and dance on campus. In addition to student performances, the center hosts more than a dozen professional events each year, and the annual convocation and other ceremonial events take place there as well. Lectures, community events, and recitals for music students round out the hall's daily schedule.

When the Weis Center was constructed in 1988, its automated rigging control system included 15 line shafts and a Shamrock controller designed and manufactured by J. R. Clancy, Inc.

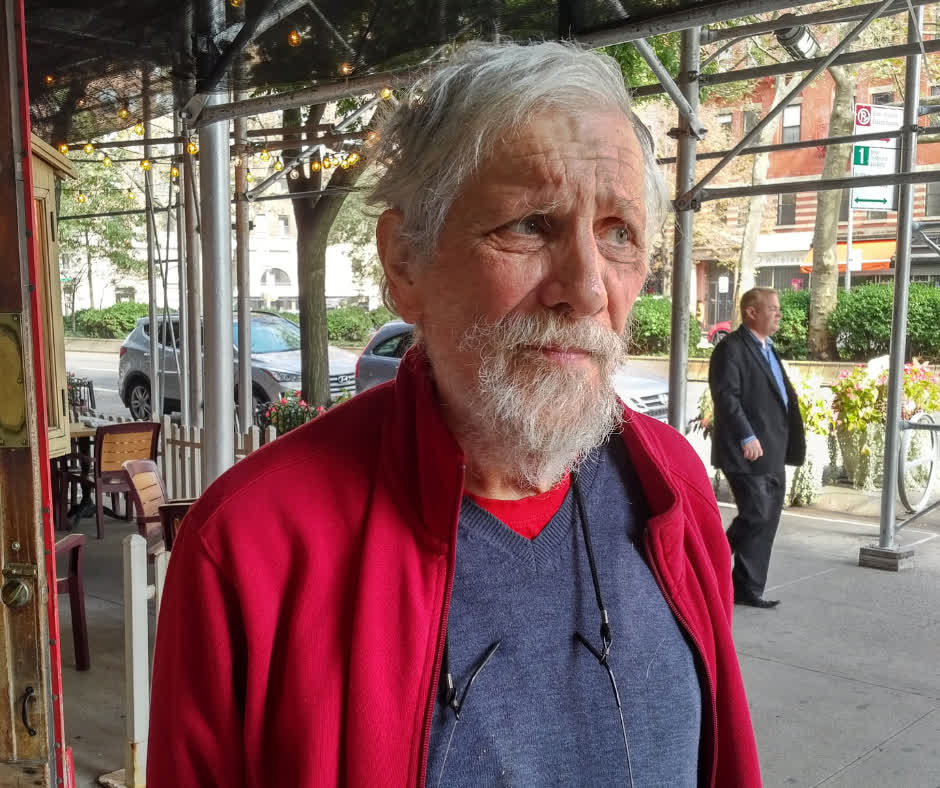

That system worked well until 1995 when, as Dale Hourlland, technical director and lighting designer at the Weis Center, explained, "the Shamrock was damaged by a power anomaly, which also took out the computer that ran the lifts in our orchestra pit, and our lighting system.

"We replaced the Shamrock with the new Shamrock 5000 – also from Clancy – which we had until very recently. It's pretty impressive to say that we had the same control system from 1995 until now."

While the system ran efficiently throughout its lifespan, it had begun to show some signs of progressive aging by 2009. "Everything would work fine, and then one day I'd turn it on and half the linesets wouldn't work," Hourlland said. "I'd have to turn it off and turn it back on, and then it would be fine."

In the meantime, newer systems had come onto the market with features the older system did not provide. "The previous system was really good for what it did," Hourlland said. "But the old system had no targeting, no feedback. It didn't have a good, clear view of the rigging system and what it was doing."

In early 2010, when the 15-year-old controller's hardware began to reach the end of its usefulness, Hourlland called J. R. Clancy.

Hourlland worked closely with Larry Eschelbacher, Clancy's manager of controls engineering to install Altus.

Altus allows Hourlland and his student crew to create up to 200 cues, with different speeds and targets for each hoist. The twelve-inch touch screen is designed to make it easy to create cues and run shows. When variable speed hoists are in place, users can set acceleration and deceleration velocity, creating dramatic visuals for dramas, musicals, and concerts. Altus plays the programmed movements reliably, allowing modifications on the fly during the performance. Altus is made from industrial grade components-including the operating system used for mission-critical systems like elevators and computer-controlled manufacturing.

Eschelbacher and the Clancy team made some modifications that allowed Altus to speak directly to the line shaft hoists in place. "We replaced the old field bus with Profibus DP communication, and modified the communication syntax from Shamrock 5000 to Altus syntax," Eschelbacher explained. "It was a simple field installation. We did this in a matter of days. We've done this on several jobs, and we do it successfully."

"The new control system is phenomenal," Hourlland said. "Altus is very intuitive, and there's plenty of feedback there. You know all the time what things are doing and when they are doing them." This is particularly important in a college setting, where student crew members can change every semester-or even every week, depending on their course schedules and availability.

As a technical director, Hourlland works with all kinds of computer systems, from lighting boards to sound recording consoles. "There's always that occasion when you're sitting at a light board or in a studio, and you think, ‘I really wish this would do this,'" he said. "Altus does all of those things we wished for. It's everything it should be-everything you'd expect a rigging controller to be."

The versatility of the rigging system was only one factor in the decision to return to Clancy, Hourlland noted. "One of the best things about Clancy is the fact that I can call up and say, ‘Here is my problem,' and within 24 hours I have a solution," he said. "If someone's considering a company to do something for their theatre, it too often becomes an issue of the bottom line. I will always push Clancy for rigging, because if there's something going on, they will be there to fix it. That's the most important thing in the end."

For more information, please visit www.jrclancy.com .