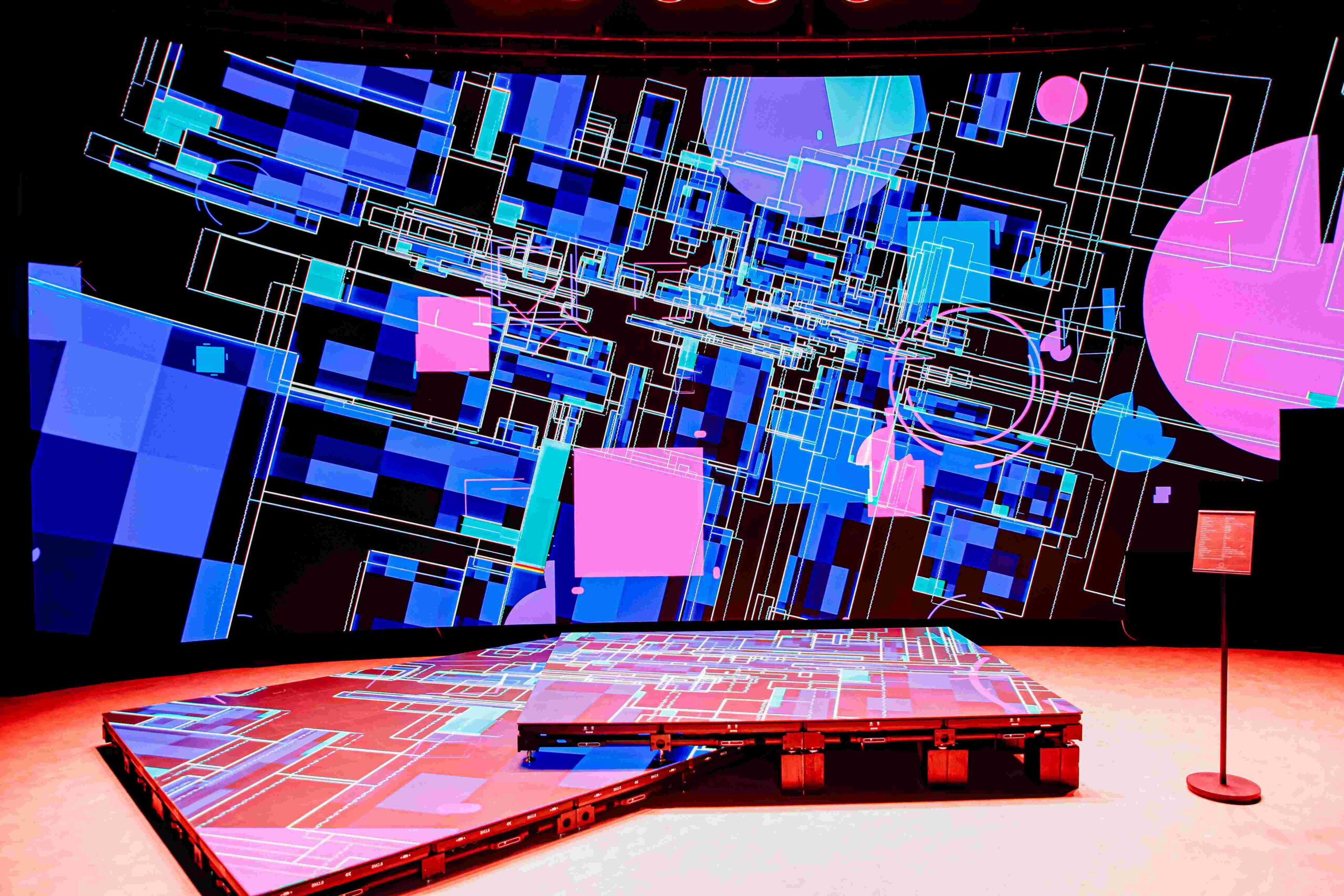

SHEFFIELD, U.K. – For the Sheffield People’s Theatre production of A Dream, described as a “modern-day mash up of Shakespearan romance,” the production team made use of ModTruss as a structural piece of scenery. The structure was a 37 by 19 foot platform on 8-foot uprights. It was made up of the three available sizes of aluminum ModTruss – 3″, 6″ and 12″. The production was presented in Sheffield’s Crucible Theatre.

More details from Triple E (www.3-eee.com):

ModTruss, the industry-changing modular truss and winner of the ABTT Engineering Product of the Year 2015, has been used for the first time in the UK as a structural piece of scenery at Sheffield’s Crucible theatre. At the end of June, a team from Triple E travelled up to The Crucible to support the installation of ModTruss for the Sheffield People’s Theatre production of A Dream, described as a ‘modern-day mash up of Shakespearan romance’. The structure was a 37′ x 19′ platform on 8′ uprights made up of the three available sizes of aluminum ModTruss – 3″, 6″ and 12″.

“The front span is 5.5m and had to be supported between two pillars. Achieving this with standard scaffold is do-able but would mean that we’d end up with a massive frontage to the set which wasn’t desirable for the designer,” Stuart West, Technical Manager for Sheffield Theatres, explains. “However, a 12″ box of ModTruss could do the span with no problems at all; we were able to maintain the sightlines the designer wanted whilst having something structurally strong enough that also gave us the depth of the floor that we needed. After reading about ModTruss we knew it was the only product on the market that could fulfil the design brief.”

Not only was the pre-production process with Triple E “a dream come true” and “very, very easy” but so was the build. The crew commented that they thoroughly enjoyed the day as ModTruss is not only easy to put together but vastly different from anything else available. Not only that, it is so lightweight no heavy lifting was required.

“Building the structure was very exciting,” West continues. “The opportunity to work with what is effectively Meccano for adults was a lot of fun; it brought back a lot of childhood memories for all of the crew and we had a great day exploring and experimenting with the structure. It was so simple! We followed the drawings we got from Triple E – it was almost like constructing by numbers.

“The lighting crew loved that they could quickly and easily put in suspended scaff tubes on half couplers. They could even suspend lighting fixtures straight from the structure. The ModTruss also enabled them to hide certain fixtures within the structure leaving clean lines on the faux ceiling underside.”

Cable management is always a big task in a set. However, ModTruss makes it simple, as West explains: “It’s the easiest way to distribute cables across the structure and avoid trip hazards; you can run it along all the supporting beams, cut a hole in your show floor and it pops out where you need it.”

West was so impressed with ModTruss that he foresees using it in the future, commenting that he even wishes it had been available for past projects: “On previous productions such as Oliver in 2013 we had to use a scaffolding structure that didn’t quite facilitate the needs of the production. ModTruss would’ve been the ideal solution.

“It’s a product that allows you to have infinite possibilities and build something that seems to be custom out of a standard box of parts. It’s the ultimate tool in any construction process.”

ModTruss is available throughout Europe from Triple E.